2026 Best Mixing Equipment in Laboratory for Optimal Results?

In the fast-evolving world of science, precise results depend heavily on quality. Mixing Equipment In Laboratory plays a crucial role in this process. Dr. Emily Chen, an expert in laboratory technologies, once stated, "The right mixing equipment can transform the accuracy of your experiments." This underlines the importance of selecting optimal tools.

Laboratories often face challenges with mixing efficiency. Not all equipment delivers the desired uniformity. Some mixers may not adapt well to various materials. Inconsistent results can lead to frustration. Researchers sometimes overlook these issues, thinking all mixers perform similarly. They often encounter unexpected variations in their data.

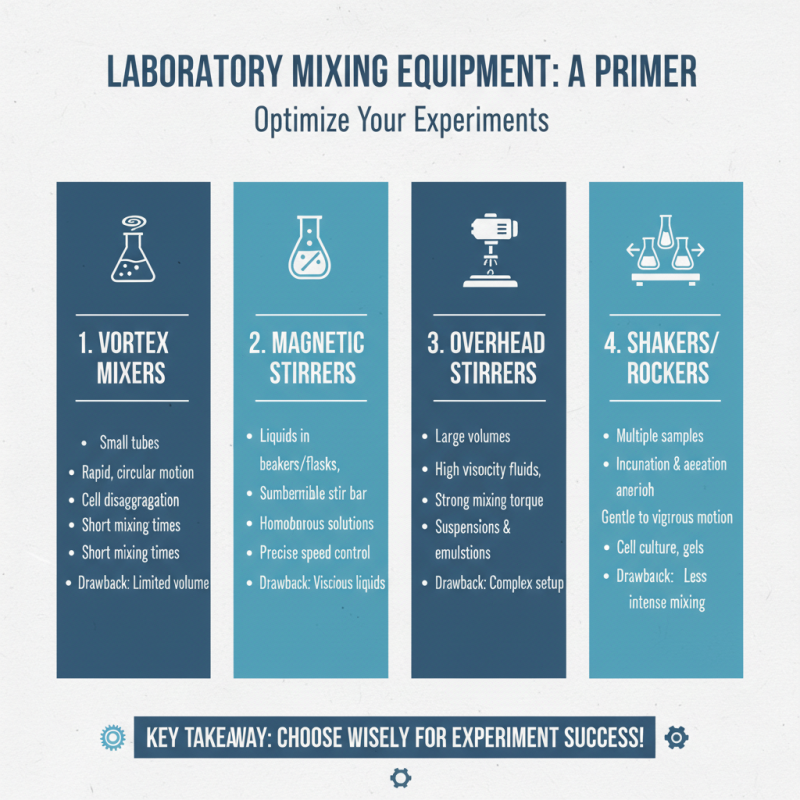

It's vital to consider different mixing technologies available. Choices range from magnetic stirrers to high-shear mixers. Each type has its strengths and weaknesses. Selecting the wrong one can hinder experimental success. Reflecting on past experiences can help improve future equipment choices. This insight is key in achieving optimal results.

Types of Mixing Equipment Commonly Used in Laboratories

Mixing equipment plays a vital role in laboratory settings. Different types of mixers are necessary for various applications. Each type offers unique advantages and challenges. Selecting the right mixer can significantly affect your experiments.

Commonly used mixing equipment includes vortex mixers, magnetic stirrers, and homogenizers. Vortex mixers are great for quick, effective mixing of small samples. They generate rapid circular motion, which blends the contents thoroughly. However, they may not be ideal for larger volumes. Magnetic stirrers are versatile. They use a magnetic field to rotate a stir bar within the container. While they provide consistent results, users sometimes face difficulty with viscous liquids.

Homogenizers are essential for emulsifying or dispersing samples. They create high shear forces to achieve uniformity. Despite their efficiency, they can generate heat that may alter sensitive samples. Understanding these devices’ limitations is crucial for optimal results. Experimentation with each type can lead to better performance and outcomes. Proper maintenance and calibration of mixing equipment are also vital to ensure accuracy and reliability.

Factors to Consider When Choosing Laboratory Mixing Equipment

When selecting laboratory mixing equipment, several factors come into play. The type of materials to be mixed is crucial. Different mixtures require specific conditions. For instance, some substances may need gentle mixing, while others necessitate vigorous agitation. Understanding these differences leads to better outcomes.

Another vital factor is the equipment's capacity. Ensure the device can handle your desired volume. Sometimes, larger mixers are tempting. However, using oversized equipment for small tasks may lead to inefficiencies. This can compromise results. Pay attention to speed settings, too. Adjustable speeds often offer flexibility for various applications.

Lastly, consider maintenance and ease of use. Complicated equipment may pose challenges. Simpler devices can save time and reduce frustration. Reflect on how often you will use the mixer. Frequent use requires durable, dependable equipment. Balancing these aspects is essential for optimal mixing results.

2026 Best Mixing Equipment in Laboratory for Optimal Results

| Mixing Equipment Type |

Speed Range (RPM) |

Volume Capacity (L) |

Power Consumption (W) |

Material Compatibility |

| Magnetic Stirrer |

100 - 2000 |

0.5 - 20 |

50 - 200 |

Glass, Plastic, Metal |

| Homogenizer |

500 - 25000 |

1 - 100 |

200 - 1000 |

Liquid and Viscous Materials |

| Vortex Mixer |

2000 - 3000 |

0.1 - 5 |

30 - 100 |

Plastic, Glass |

| Planetary Mixer |

10 - 500 |

5 - 50 |

300 - 1500 |

Powders, Liquids, Slurries |

Top Laboratory Mixers for Different Applications

Choosing the right laboratory mixer is crucial for achieving optimal results. The market offers a variety of mixers tailored to different applications. According to industry reports, over 60% of labs experience mixing challenges that impact research outcomes. A well-suited mixer can alleviate these issues.

For instance, low-speed mixers are effective for delicate samples. They preserve shear-sensitive materials, crucial in biochemical applications. On the other hand, high-shear mixers excel in emulsion and dispersion tasks. They are common in pharmaceutical labs where particle size uniformity is paramount. Many researchers underestimate the importance of selecting the right type.

Many labs overlook maintenance. Regular checks can enhance performance and lifespan. Statistical analyses reveal that 30% of equipment failures stem from poor upkeep. Understanding specific needs will guide decisions. Not every mixer fits every situation. Evaluating workflows can lead to better equipment utilization. Proper mixer selection contributes to research quality and efficiencies in the long run.

Best Practices for Using Mixing Equipment in a Laboratory

Effective mixing in a laboratory is crucial for achieving optimal results. Proper practices are essential to prevent errors. According to a study by the American Chemical Society, uneven mixing can lead to significant variations in experimental outcomes, affecting over 30% of results. This highlights the need for attention to detail.

When using mixing equipment, always calibrate your tools. Calibration ensures uniformity and precision. Neglecting this step can introduce variability. It's also essential to maintain the equipment regularly. A report from the Journal of Lab Automation noted that 25% of equipment failures stem from poor maintenance. This can disrupt experiments, leading to wasted time and resources.

Choose the right mixer type based on your materials. Some liquids require gentle mixing, while others need vigorous agitation. Using incorrect equipment can compromise results. Don't overlook the importance of safety. Improper handling of mixers can lead to accidents. Always wear appropriate protective gear.

2026 Best Mixing Equipment in Laboratory for Optimal Results

This chart illustrates the mixing efficiency of various laboratory mixing equipment available in 2026. The data reflects the performance of each type based on a series of controlled experiments, indicating the optimal choices for effective mixing results.

Maintaining and Troubleshooting Laboratory Mixing Equipment

Maintaining and troubleshooting laboratory mixing equipment is essential for achieving optimal results.

Regular inspections help identify wear and tear. Look for

leaks or unusual noises during operation. These issues

can directly affect mixing efficiency and accuracy.

Calibration is another critical aspect. Over time, even the

best equipment can drift from its settings. Regular checks ensure that measurements remain precise.

It's vital to document any changes or irregularities noticed during use. This record can provide

insights into potential problems.

Don't ignore the user manual. It often

contains troubleshooting steps specific to the equipment. Many users overlook this resource,

which can lead to repeated mistakes. A detailed review can shed light on common issues

and maintenance requirements. Remember, keeping equipment in top shape benefits overall

laboratory productivity.

Products

Lab UHT/HTST Pilot Plant

Lab UHT/HTST Sterilizer

Inline Lab Homogenizer

Lab Direct-Steam-Injection Sterilizer

Lab Aseptic Filling Cabinet

Pilot Plant for Dairy & Juice

Water Bath Mixing & Fermenter Unit

Pilot-Scale Multi-Effect Falling-Film Evaporation

Pilot-Scale All-in-One Carbonator-Filler

Vacuum Chopper Mixer

Solutions

Service & Support

About

News

Blog

Contact Us