Best UHT System for Preserving Food Quality and Safety?

In today's food industry, ensuring quality and safety is essential. The UHT system, or Ultra High Temperature system, is a technology designed to meet these demands. By heating food to high temperatures, it kills harmful microorganisms and extends shelf life.

Many producers rely on UHT systems for beverages and dairy products. This method maintains flavor and nutrients better than traditional processes. However, some questions arise about the impact on taste and texture. Does food always retain its quality after such treatment?

Industries must weigh the benefits against potential drawbacks. Each UHT system varies in design and efficiency. Some might not be suitable for specific products. Exploring these differences can guide producers in making better choices. Finding the best UHT system may not be straightforward, but it is crucial for success in today’s market.

Understanding UHT Technology and Its Application in Food Preservation

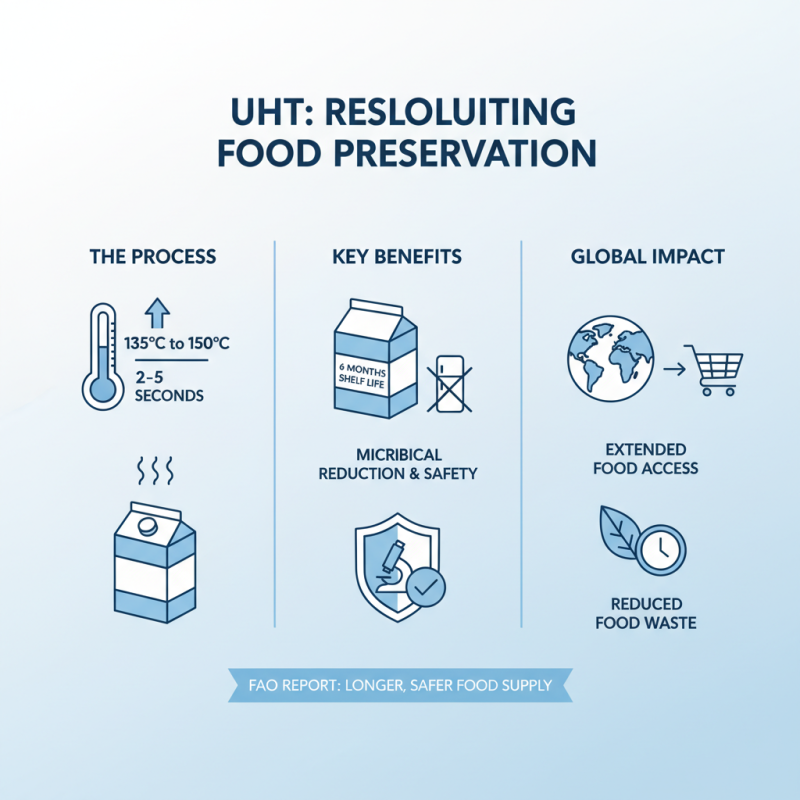

Ultra-High Temperature (UHT) technology has revolutionized food preservation. This method involves heating food to 135-150°C for a short duration. A report from the Food and Agriculture Organization notes that UHT can extend shelf life for up to six months without refrigeration. This is crucial for maintaining food quality and safety. It minimizes microbial growth, reducing the risk of foodborne illnesses.

However, the process is not flawless. While UHT preserves nutrients, some sensitive vitamins can degrade. A study published in the Journal of Food Science found that vitamin C levels drop significantly after UHT processing. Consumers may overlook this, believing UHT products retain all nutrients. Additionally, taste can sometimes be altered, leading to concerns about product acceptance.

UHT technology is not universally applicable. Certain foods may not benefit as much from this method. For example, texture changes can occur in dairy products. Reports indicate that milk treated with UHT can develop a slightly cooked flavor. Understanding these nuances is essential for producers and consumers alike. Balancing safety and quality requires continuous improvement and reflection on the technology's limitations.

Key Benefits of UHT Systems for Food Quality and Safety

UHT, or ultra-high temperature processing, is crucial for maintaining food quality and safety. It involves heating food to high temperatures for a short period. This process significantly reduces the microbial load without compromising flavor or nutrition. As a result, products last longer and remain safe for consumption.

One key benefit of UHT systems is their ability to preserve nutrients. Studies indicate that vitamins and minerals retain their potency better than in traditional methods. However, some argue there may be slight nutrient loss. Achieving a balance between safety and preservation can be challenging.

UHT technology also fosters convenience in food storage. Packaged UHT products can be stored without refrigeration until opened. This reduces food waste and storage costs. Yet, it's important to consider that excessive reliance on UHT can limit variety in diets. While it enhances safety, it also raises questions about freshness. Overall, UHT systems undoubtedly support food safety while contributing to a more sustainable food supply. But, there’s room for ongoing improvement and innovation in this space.

Comparing Different UHT Systems: Which Is the Most Effective?

When comparing different UHT (Ultra-High Temperature) systems, effectiveness varies significantly. Studies show that UHT processing effectively reduces microbial load, preserving food quality. For instance, a 2021 report indicated that UHT can achieve 99.9999% reduction in bacteria, extending shelf life by months.

Different UHT systems, such as indirect and direct methods, have unique strengths. Indirect methods heat food using a heat exchanger, which may preserve taste and nutritional value more effectively. Direct systems inject steam directly into the product. Each method affects flavor and texture. Some food products may not react well to steam injection, resulting in an off-taste.

**Tip:** Consider the type of food when choosing a UHT system. Not all foods respond similarly to high temperatures. For instance, dairy may benefit more from indirect methods than juices.

Cost is another consideration. Initial investments for advanced UHT systems can be high. Factors include equipment and maintenance. Nevertheless, potential savings in spoilage and extended shelf life often justify the costs.

**Tip:** Regular maintenance is crucial. Downtime from equipment failure can lead to product losses. A clear maintenance schedule ensures consistent operation. Balancing effectiveness and cost is key when deciding on the right UHT system.

Factors to Consider When Choosing a UHT System for Your Needs

When selecting a UHT system, various factors play a crucial role. You need to think about capacity. What volume of product do you intend to process? If you underestimate, you may face delays. Overestimating can lead to unnecessary costs. It’s all about finding that sweet spot.

Another factor is energy consumption. Efficient systems save money. Look for UHT systems that minimize energy use while maximizing output. You might also want a setup that integrates easily with existing infrastructure. Compatibility can save time during installation.

Finally, consider maintenance needs. Some UHT systems require frequent upkeep. This can lead to machine downtime. A system with simpler maintenance can be more reliable. Evaluate these factors carefully. Each decision impacts product quality and safety. The right UHT system should balance efficiency, cost, and ease of use.

Case Studies: Successful Implementation of UHT Systems in Food Industry

The food industry has seen remarkable advancements with the implementation of UHT systems. These systems allow for longer shelf life while preserving the quality and safety of products. A case study from a dairy facility illustrates a significant improvement in milk shelf life. By utilizing UHT processing, the facility reported a 90% reduction in spoilage rates.

Another example comes from the juice sector. One juice manufacturer integrated UHT to maintain flavor integrity and nutrients. This not only satisfied customers but also reduced waste drastically. However, the adjustment period was challenging. Some employees initially struggled with new equipment, leading to production inconsistencies. This highlighted the importance of proper training.

Tips: Ensure that staff conducts regular maintenance on UHT machines. Daily checks can prevent issues before they arise. Additionally, focus on clear communication within the team about production standards. Enhancing teamwork can lead to better results and higher quality outputs.

Products

Lab UHT/HTST Pilot Plant

Lab UHT/HTST Sterilizer

Inline Lab Homogenizer

Lab Direct-Steam-Injection Sterilizer

Lab Aseptic Filling Cabinet

Pilot Plant for Dairy & Juice

Water Bath Mixing & Fermenter Unit

Pilot-Scale Multi-Effect Falling-Film Evaporation

Pilot-Scale All-in-One Carbonator-Filler

Vacuum Chopper Mixer

Solutions

Service & Support

About

News

Blog

Contact Us