Top 10 Best Vacuum Emulsifiers for Perfect Mixing and Emulsion Stability

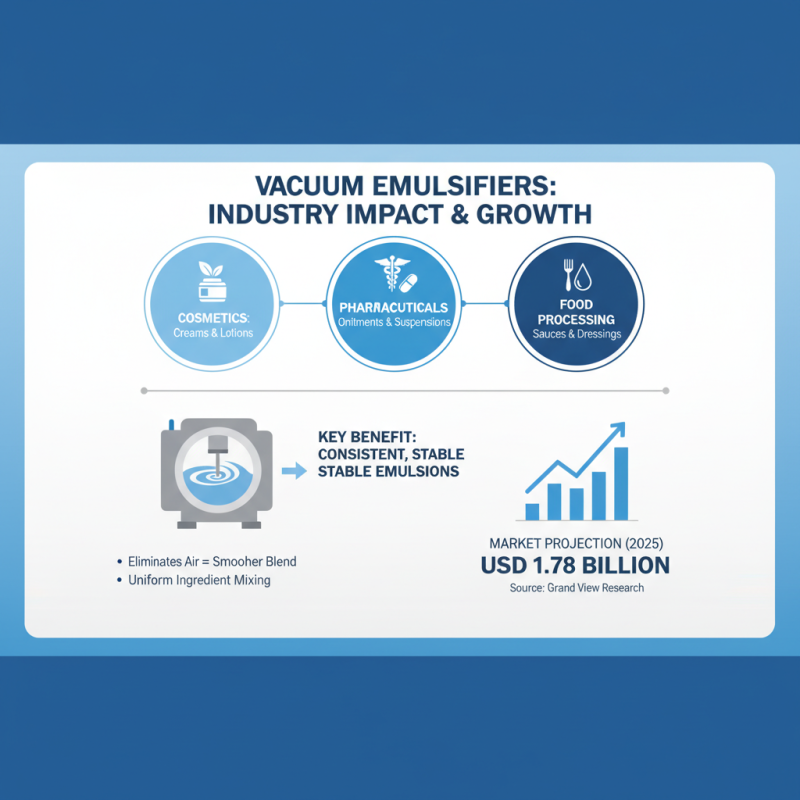

In the realm of advanced manufacturing processes, Vacuum Emulsifiers play a pivotal role, especially in industries such as pharmaceuticals, cosmetics, and food production. According to a recent industry report by Grand View Research, the global vacuum emulsifier market is expected to grow significantly, reaching an estimated value of $1.5 billion by 2025, driven by the increasing demand for high-quality emulsions and stable mixtures. This growth underscores the importance of selecting the right vacuum emulsifier, which not only ensures perfect mixing but also enhances the stability of emulsions over time.

Industry experts emphasize the transformative impact of vacuum emulsification technology. Dr. Sarah Lin, a renowned chemist in the field of cosmetic formulations, stated, “The precision and efficiency brought by vacuum emulsifiers eliminate the common challenges faced in emulsion stability, paving the way for innovative product development.” The ability of vacuum emulsifiers to operate under reduced pressure allows for the creation of finer emulsions, leading to superior texture and performance in end products. As manufacturers seek to elevate their formulation processes, understanding the top vacuum emulsifiers available in the market is essential for achieving optimal results.

Overview of Vacuum Emulsifiers and Their Applications

Vacuum emulsifiers are advanced pieces of equipment designed to produce stable emulsions and ensure a homogenous mixture of different phases, such as oils and water. These machines employ a vacuum environment to eliminate air bubbles from the mixture, which can compromise the quality of the final product. The design of a vacuum emulsifier typically includes a large tank with a high-speed rotor and stator that create intense shear forces, enabling effective dispersion and mixing of ingredients. This makes them particularly valuable in industries like cosmetics, pharmaceuticals, and food processing, where uniformity and stability are critical.

The applications of vacuum emulsifiers are diverse, ranging from the production of creams and lotions in skincare to the formulation of sauces, dressings, and even emulsified pharmaceuticals. Their ability to efficiently mix viscous materials under vacuum conditions allows for the creation of high-quality emulsions that maintain their stability over time, which is essential for shelf life and performance. As a result, vacuum emulsifiers play a pivotal role in enhancing product quality and consistency, making them an indispensable tool in modern manufacturing processes across various sectors. Such technology not only improves efficiency but also reduces the likelihood of separation in final products, thereby ensuring that consumers receive a reliable and effective product.

Key Features to Look for in Vacuum Emulsifiers

When selecting a vacuum emulsifier, there are several key features to consider that can enhance the mixing process and improve emulsion stability. Firstly, the design of the emulsifier is paramount. Look for a machine with a high-shear mixer, as it is vital for generating the shear forces necessary to break down particles and ensure uniform distribution within the mixture. A well-designed rotor-stator assembly enhances the mixing efficiency, allowing for finer emulsions and reducing the likelihood of separation over time.

Another important feature is the vacuum capability of the emulsifier. By operating under vacuum conditions, the emulsifier can minimize the introduction of air into the mixture. This is crucial in preventing oxidation and maintaining the quality of the final product. Additionally, the ability to heat or cool the mixture during processing can further enhance emulsion stability by controlling viscosity and altering the properties of the ingredients being mixed. Effective temperature regulation is essential for maintaining consistent emulsion characteristics, particularly in temperature-sensitive formulations.

Finally, ease of cleaning and operation should not be overlooked. A vacuum emulsifier that offers quick disassembly and access to key components will save time during maintenance and reduce downtime in production. User-friendly controls and automation features also enhance operational efficiency, making the emulsifier not only more effective but also easier to integrate into existing production lines.

Top 10 Vacuum Emulsifiers: Specifications and Performance

Vacuum emulsifiers have gained prominence in various industries, particularly in cosmetics, pharmaceuticals, and food processing, due to their ability to achieve consistent mixing and stable emulsions. These machines utilize vacuum technology to eliminate air from the product, which allows for a smoother, more uniform blend of ingredients. According to a recent market analysis by Grand View Research, the global vacuum emulsifier market is projected to reach USD 1.78 billion by 2025, driven by the increasing demand for high-quality emulsions in consumer products.

When examining the specifications and performance of top vacuum emulsifiers, several key factors emerge as crucial for optimal functionality. These include the mixing speed, the ability to maintain a constant temperature, and the effectiveness of the homogenization process. For instance, a typical high-performance vacuum emulsifier operates at speeds up to 3,000 RPM and can achieve particle sizes as small as 10 microns, which is essential for the stability of emulsions. Additionally, an efficient cooling system is vital to control the temperature during emulsification, preventing heat-induced degradation of sensitive ingredients. Industry reports indicate that the right combination of these specifications can enhance the emulsion's shelf life and improve sensory properties, making the end product more appealing to consumers.

Furthermore, performance metrics such as the viscosity of the final product, emulsion stability over time, and recovery rates during processing are critical considerations. Studies have shown that emulsions processed with advanced vacuum emulsifiers exhibit significantly improved stability, with some formulations ensuring up to 95% stability after six months of storage. This level of performance underscores the importance of investing in high-quality equipment to meet the growing demands of precision mixing and product consistency in competitive markets.

Comparative Analysis of the Leading Vacuum Emulsifiers

In the realm of cosmetic and food production, the quality of emulsions plays a vital role in determining the final product's stability and texture. A comparative analysis of leading vacuum emulsifiers reveals the critical aspects that influence their effectiveness. The primary factors include the size and distribution of particles, as well as the pumping capacity, which affects how thoroughly ingredients are mixed. High-performance emulsifiers are designed to minimize air entrapment, ensuring a smoother consistency and enhancing the stability of the emulsion over time.

Additionally, the ease of operation and maintenance of these emulsifiers can significantly impact production efficiency. User-friendly interfaces that allow for precise control over temperature and mixing speeds offer significant advantages in achieving optimal conditions for emulsification. The materials used in construction also play a role in the durability and sanitation of these machines, as they must withstand frequent cleaning and varying manufacturing environments. As the demand for high-quality emulsions grows across various industries, understanding the comparative features of vacuum emulsifiers is essential for manufacturers seeking to enhance their production processes.

User Reviews and Recommendations for Each Emulsifier Model

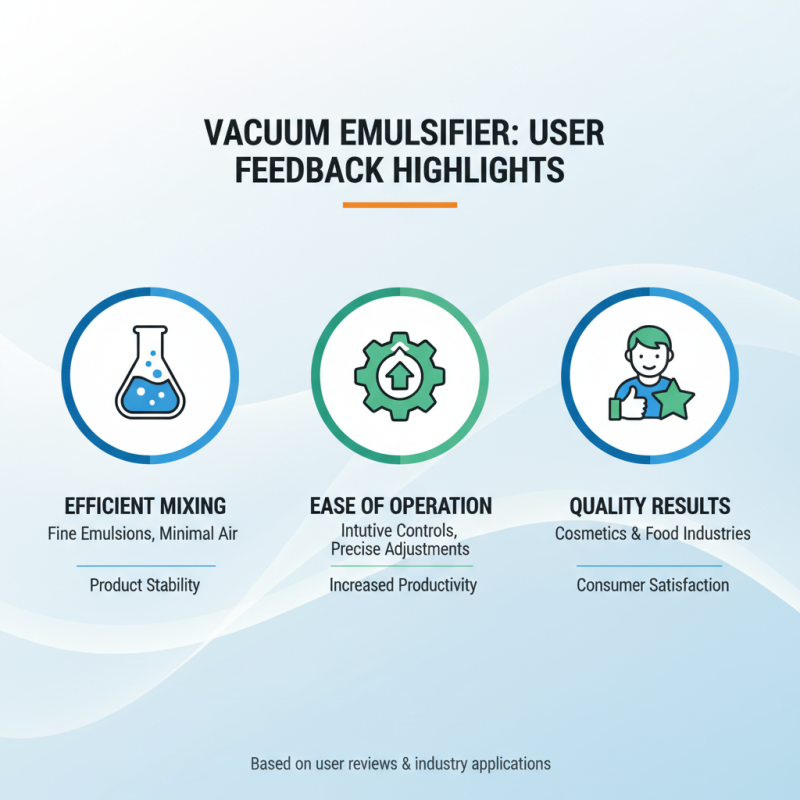

When selecting the right vacuum emulsifier, user feedback plays a crucial role in guiding potential buyers toward the best choice for their specific needs. The reviews often highlight the efficiency of the mixing process, with many users praising the emulsifiers for their ability to achieve fine emulsions with minimal air incorporation. This is particularly important in industries like cosmetics and food processing, where the texture and stability of the final product can significantly impact consumer satisfaction. Users frequently note the ease of operation, with intuitive controls that allow for precise adjustments during the mixing process, enhancing overall productivity.

Recommendations from experienced users often focus on the importance of build quality and maintenance. Many highlight models that are easy to clean and maintain, as this directly affects operational efficiency in fast-paced production environments. Additionally, feedback often emphasizes the need for robust customer support and available spare parts, as a reliable production line is essential for maintaining consistent product quality. By considering these user insights, prospective buyers can make informed decisions and select a vacuum emulsifier that meets their specific mixing requirements and contributes to their production efficiency.

Products

Lab UHT/HTST Pilot Plant

Lab UHT/HTST Sterilizer

Inline Lab Homogenizer

Lab Direct-Steam-Injection Sterilizer

Lab Aseptic Filling Cabinet

Pilot Plant for Dairy & Juice

Water Bath Mixing & Fermenter Unit

Pilot-Scale Multi-Effect Falling-Film Evaporation

Pilot-Scale All-in-One Carbonator-Filler

Vacuum Chopper Mixer

Solutions

Service & Support

About

News

Blog

Contact Us