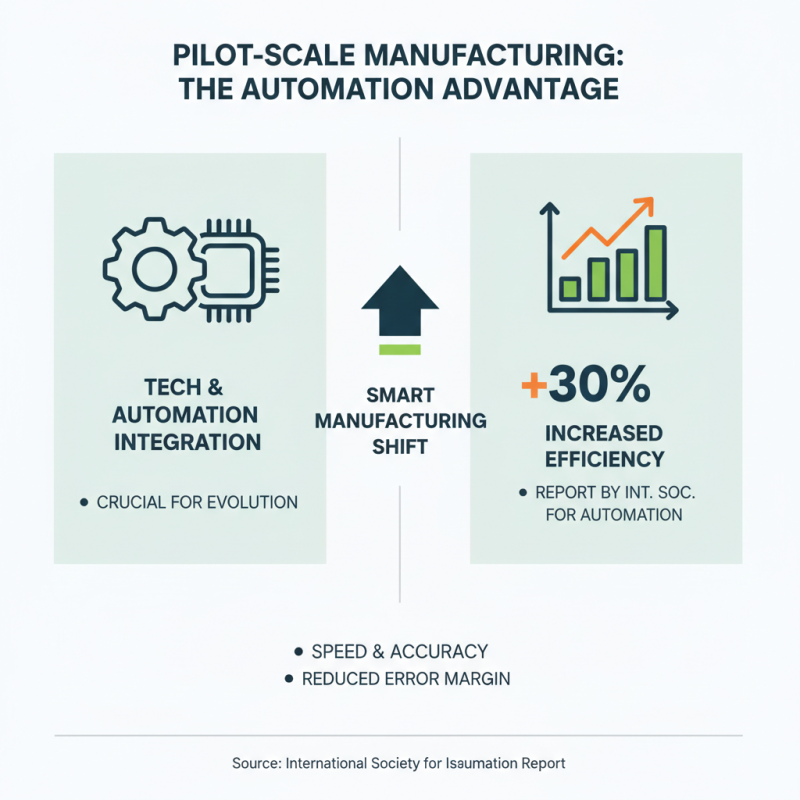

In the rapidly evolving landscape of pilot scale manufacturing, integrating technology and automation is crucial. According to a recent report by the International Society for Automation, companies that utilize advanced automation techniques report a 30% increase in efficiency. The shift towards smart manufacturing has been significant. It's not just about speed but also accuracy. Automated systems reduce the margin for error in production processes.

However, many businesses still struggle with implementation. A survey indicated that 45% of manufacturers do not fully leverage automation. This gap can lead to inefficiencies, affecting growth potential. For instance, while some firms integrate real-time data analytics, others remain reliant on outdated practices. It’s imperative to recognize that technology can only enhance operations if fully embraced.

Moreover, the financial implications are profound. Industry data shows that companies investing in automation technologies often see returns of up to 25% within three years. Yet, companies face challenges. Resistance to change, training deficits, and upfront costs all pose significant hurdles. Reflecting on these issues can guide factories towards adopting an effective growth strategy. Ultimately, maximizing pilot scale manufacturing relies heavily on embracing innovative solutions.

Products

Lab UHT/HTST Pilot Plant

Lab UHT/HTST Sterilizer

Inline Lab Homogenizer

Lab Direct-Steam-Injection Sterilizer

Lab Aseptic Filling Cabinet

Pilot Plant for Dairy & Juice

Water Bath Mixing & Fermenter Unit

Pilot-Scale Multi-Effect Falling-Film Evaporation

Pilot-Scale All-in-One Carbonator-Filler

Vacuum Chopper Mixer

Solutions

Service & Support

About

News

Blog

Contact Us